Protection:

On-time Dispatch Guarantee

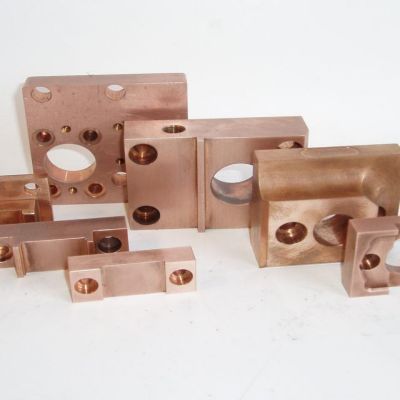

(1) Copper and copper alloys have good conductivity, thermal conductivity, good wear resistance, high strength, and plasticity, and can be cast and forged. They are widely used in industry.

(2) Copper alloys are divided into four categories: pure copper, brass, bronze and white copper.

(3) Processing precautions: copper alloy has low hardness and strength, and it is easy to deform under the action of cutting force and clamping force. During clamping, attention shall be paid to prevent pinching and crushing. During clamping, attention shall be paid to not pinching and compressing. For larger castings, more parts shall be pressed and the pressing force shall be small. Copper alloy is easy to deform after being heated. The finishing allowance should be small, and the cutting amount should be 0.1-0.2mm. After semi-finishing milling and finishing milling, the dimension should be measured after the workpiece is cooled to normal temperature.