Our CNC turning machine can shorten the product manufacturing process chain and improve production efficiency. A variety of special tools can be installed.

The machining parts have high precision and stable quality. The positioning accuracy and repeated positioning accuracy of the surface grinder are very high.

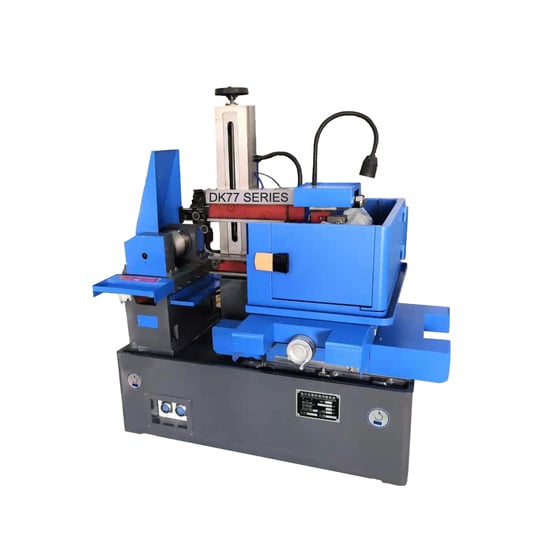

Our fast wire cutting has the advantage of being cheap and high quality. The needs for general and common processing are still rather substantial.

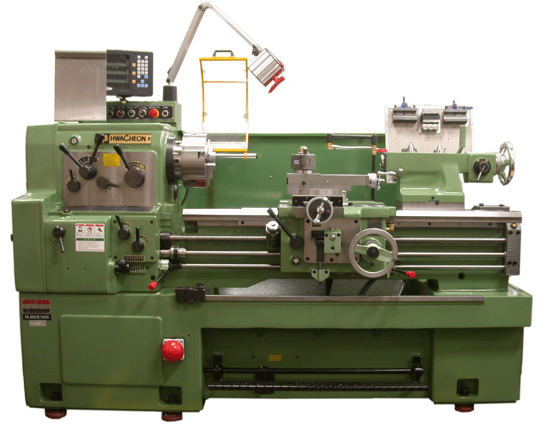

Our turning lathe can use high-performance vector control flexibly with low frequency large torque and stable and reliable output.

Medium wire cutting retains many excellent qualities of fast wire cutting, such as simple structure, relatively low cost, excellent process effect, less loss in use, etc.

Our 4-axis CNC engraving machines can be programmed to reduce human interference in specific manufacturing processes to improve production efficiency.

Our CNC milling machine can shorten the product manufacturing process chain and improve production efficiency. A variety of special tools can be installed, and the new tool arrangement can reduce tool change time and improve processing efficiency. CNC machine tools can complete all or most of the processing procedures in one clamping, thus greatly shortening the product manufacturing process chain. In this way, the production auxiliary time caused by the change of the loading card, the manufacturing cycle and waiting time of the tools and fixtures are reduced, which can significantly improve production efficiency.

The advanced slow wire processing machine adopts the non-electrolysis-proof pulse power supply with zero average voltage, and the damage of electrolysis has been reduced to a low level. In addition, due to the improvement of pulse power supply, high peak value and narrow pulse width (microsecond level) are generally used, and most of the materials are thrown out of the gas phase, which takes away a lot of heat, the surface temperature of the workpiece cannot rise, and the phenomenon of cracking is greatly reduced; not only high processing efficiency, but also greatly improves the surface quality.

1. Less friction during machining and longer life of milling cutter

2. Easy clamping, no vibration, and high precision of the machined surface

3. Easy to make and set, suitable for long and thin workpieces

4. Less power consumption

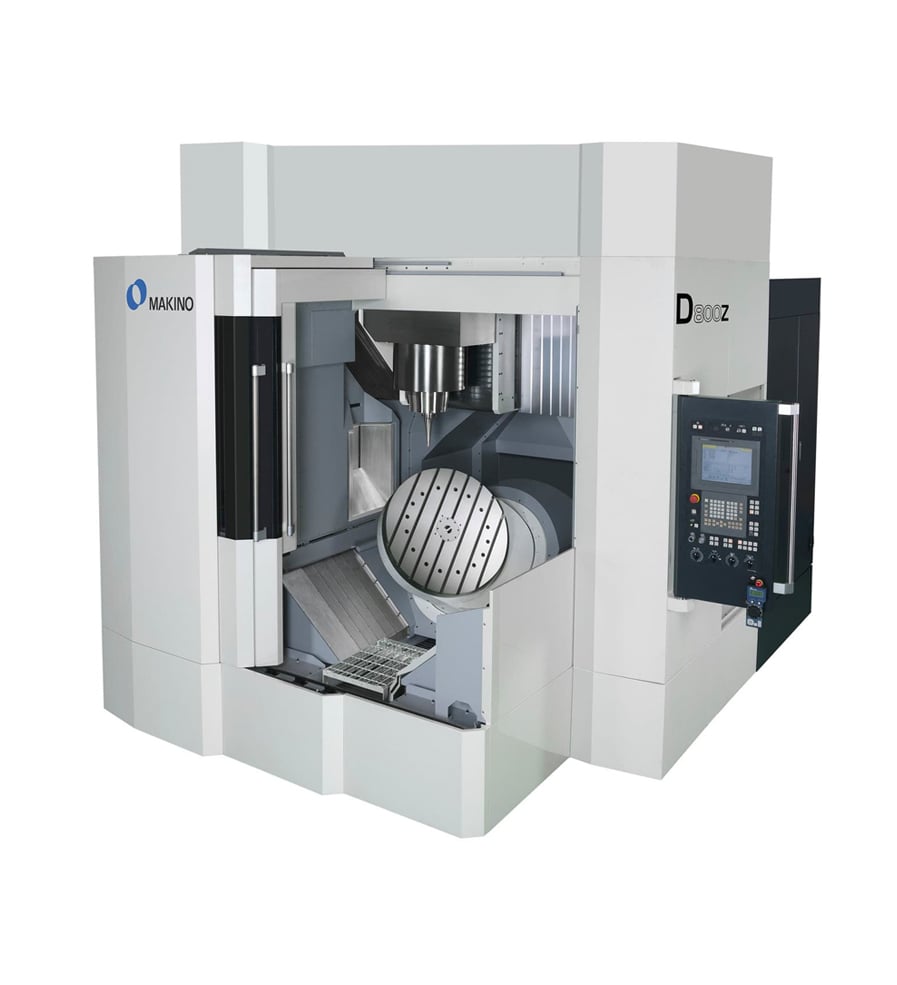

1. It is suitable for processing complex special-shaped parts. The 5-axis machining center can realize the processing of complex parts that are difficult to achieve or basically unmachinable by general machining centers.

2. High precision machining. The five-axis machining center completes the inspection by dimensional analysis of the material through five-axis positioning, so the accuracy of the five-axis vertical machining center is higher than that of the ordinary machining center.

3. The processing is firm. It can master the computer and eliminate human error. The parts have good processing consistency and reliable quality.

4. High flexibility. When dealing with object conversion, it is generally only necessary to change the numerical control sequence, which shows good adaptability.

5. Efficient. The 5-axis machining center has high machining accuracy. The rigidity of the bed is large, and the processing volume can be automatically selected.