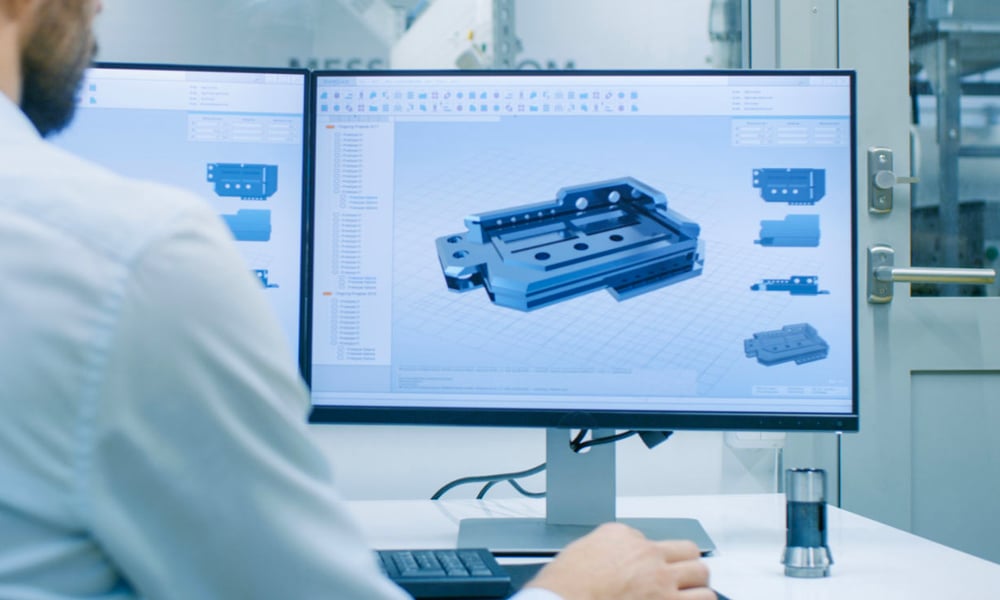

1. We provide one-to-one support service by a technical team, ensuring the long-term implementation of each process file before processing, verifying the integrity of each drawing, communicating with customers to confirm the unclear parts, and updating the process files in time so that they can be implemented smoothly.

2. We have strict incoming quality control and final inspection and we select raw materials that meet national or quoted national standards. Regular large material suppliers will provide proof of raw material production, and we will test the performance of various materials using our own equipment.

3. We will provide testing of the first sample of each product, and conduct comprehensive testing of the required data such as dimensions, accuracy, hardness, salt spray, surface treatment, etc. for each part. We ensure that the materials, procedures and processes are in accordance with the requirements and form the process file during mass production.

4. In the real production process, our quality control personnel will check the parts in production regularly, timely eliminate defective products, replenish materials, redo other processes, summarize production problems, propose and implement improvement measures, ensuring fast and efficient delivery time and after-sales.

5. Each accepted part will be treated with anti-rust, wrapping and classification packaging, and each batch will be fixed with transportation considerations such as anti-collision and anti-drop, so that each batch of goods can be safely delivered to the customer's destination.

Hexagon CMM: Compass technology, configured in the global chrome series, maintains high accuracy even at high scanning speeds. The integrated hardware and software scheme achieves maximum efficiency with guaranteed accuracy.

OMM: Different from the coordinate measuring machine using a contact probe, the image measurement system collects data on the tested components using a non-contact camera lens and image analysis software.

CCD: CCD vision inspection equipment is based on the machine vision technology of CCD camera for inspection. It has been tested for its minor error and high inspection efficiency, which can exceed 400-1200 times per minute.

Height Gauge: It can measure the height of small workpieces. The scriber with carbide head and clear LCD readout display ensure no misreading of 0.01 mm.

Sclerometer

Vernier Caliper

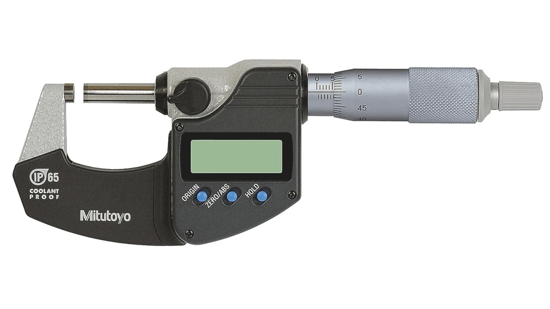

Micrometer

Go/no-go Gauge