In common processing technologies, turning is done by rotating the part, where the tool and the material are in point contact and the material is cut by the tooltip (blade).

Milling is machined by rotating the tool. The material and the tool are in linear contact. More material per unit volume can be removed at one time through the blade.

There is no essential difference between the two, nor is there any difference in machining efficiency or precision.

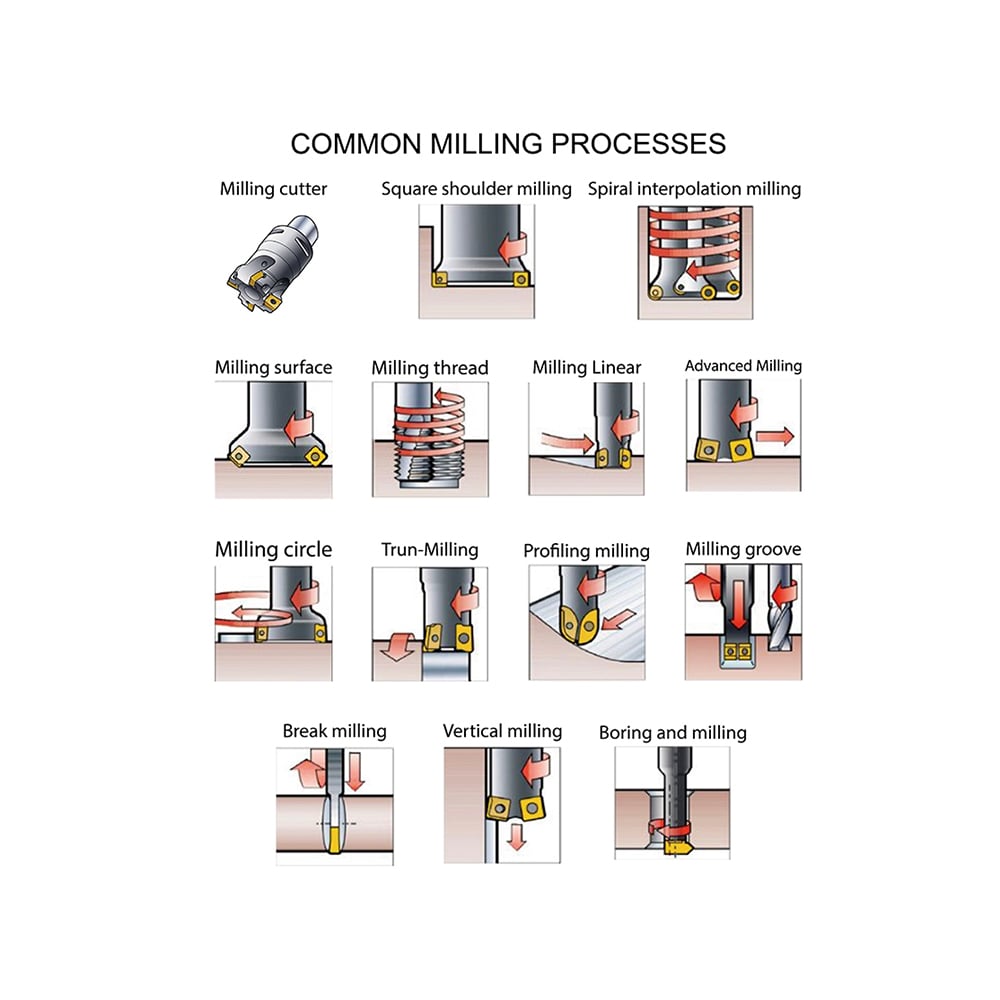

CNC milling is more applied to complex surfaces, step surfaces, helical surfaces (threads), inclined surfaces (taper surfaces), chamfers, grooves (keyways, grooves, T-grooves, etc.) with complex shapes, and complete processing of parts without replacement.

CNC milling is suitable for the processing of large quantities of special-shaped parts. The simultaneous processing of multiple parts can be realized by customizing tooling fixtures.

By optimizing the program, the processing path of continuous multiple processes can be reduced and more efficient production can be realized. Our enterprise has realized the networked control of multiple machine tools to realize the synchronous implementation and monitoring of the production process.

1. CNC milling is especially suitable for parts with strong adaptability to materials and difficult to control size or parts with particularly complex contour shapes.

2. It can process parts that are difficult or impossible to be processed by ordinary turn-milling machine tools, such as linear surface, circular arc surface, etc.

3. After one clamping and positioning, it can complete the processing of multiple processing procedures and multi-faceted and multi-type processes, such as milling, chamfering, milling round holes, drilling, reaming, reaming, boring, thread milling and so on.

4. The equipment has a high degree of automation, especially the equipment with tool magazine and automatic tool change, which can reduce labor intensity and repeat the tooling process. When the quality needs to be checked, the processing can be stopped at any time, and the continuous production cannot be adjusted after the inspection.